>Steel plate

ZINCALUME? steel

55% Aluminum Zinc coated steel which alloy coating comprised with the 55% aluminum, 43.5% zinc and

1.5% silicon. Introduced to the market in 1976, after many years of extensive research and development, it

has continuously been set as the standard for corrosion resistance. The performance lasts up to 4 times

greater than an equivalent galvanized coating.

Clean COLORBOND? steel

Overview:

For many years, the Clean COLORBOND? steel has represented technical advancement and product

innovation in Asia all the time. It has exceptional fading resistance and chalking resistance and solves the

dust adhesion phenomenon which has caused disturbances to buildings in individual countries in Asia for a

long term. In addition, its base plate for metal plating is made of the ZINCALUME? steel, so it

has an extremely long service life. It really eliminates your worries and makes your buildings keep a

constant and bright appearance.

-

Excellent corrosion resistance

-

Extraordinary fading resistance

-

Extraordinary dust adhesion resistance

-

-

Excellent mechanical properties

Excellent corrosion resistance

The Clean COLORBOND? steel uses BlueScope Steel’s famous product -

ZINCALUME? steel as its base plate, so that oxygen, water and other corrosive

substances in the air can be isolated from coming into contact with the surface of steel,

consequently making steel plates reach an ultra-long service life while allowing them to have a

constant and good appearance. The Clean COLORBOND? steel is able to provide

exceptional performance either in severe industrial environments or in oceanic environments.

Extraordinary fading resistance

We always persist in continuous technical innovation and provide products with

higher quality to you. The Clean COLORBOND? steel launched in the end of 2004 further

improves its coating system to effectively reduce the paint film degradation rate of color

coating layer, improve the chalking resistance of coating and enable more stable glossiness of

coating surface. Its extraordinary fading resistance makes buildings keep a more lasting

brand-new appearance.

Extraordinary dust adhesion resistance

For many years, air pollution has disturbed the materials used in building

projects in Asian countries all the time. When temperature and humidity is relatively high,

pollutants in air and dust particles in smoke adhere to the surfaces of buildings tightly via

airborne transmission, so that dust adhesion is caused. Once similar situations occur, dark

stain spots will be formed on the surfaces of buildings and they will be hard to remove. The

Clean COLORBOND? steel is especially researched and developed for the intrinsic

environment and relatively severe air pollution in Asia regions and adopts a revolutionary

coating system to prevent dust particles from adhering to its surface. Dust particles will

loosely settle on the surface of steel plates and regular rainwater flushing can bring them

away, consequently achieving dust adhesion prevention.

Infrared reflectivity

The Clean COLORBOND? steel has the unique heat reflection technology

Thermatech?. It can not only effectively reduce the surface temperature of buildings

and achieve the function of energy consumption reduction and energy conservation but also

further improve the stability of its color coating layer. As the surface coating of Clean

COLORBOND? steel can reflect heat in sunlight, it can effectively decrease the

surface temperature of roof.

Excellent mechanical properties

The Clean COLORBOND? steel has multiple specifications of mechanical

strength. It is mainly classified as medium-strength steel coil and high-strength steel coil.

Its outstanding mechanical properties are able to meet different requirements of either

wide-span design without beams and columns or complicated curved surface design. Medium-strength

steel plates are easy for molding. They can be processed into different plate types by means of

calendering and provide creative building effect. High-strength steel plates are suitable for

wide-span buildings without beams and columns and consistent with various traditional and modern

building styles.

>Clean COLORBOND? steel product series:

Clean COLORBOND? XRW steel

It adopts a special nano-strengthening polyester coating system. Its coating is highly weather-proof to make

buildings keep a constant and bright appearance. It is suitable for roof and wall maintenance systems.

Clean COLORBOND? XPD steel

It adopts a fluorocarbon coating system. The gloss of its coating is stable and more lasting. It is suitable

for roof and wall maintenance systems and meets artistic design requirements and the applications with high

requirements on color and glossiness stability.

Clean COLORBOND? ULTRA steel

It adopts the AZ200 ZINCALUME? steel and uses special anti-rust primer. Its ultra-strong corrosion

resistance is especially suitable for roof and wall maintenance systems in corrosive environments,

particularly in severe oceanic environments or severe industrial environments.

Clean COLORBOND? Pearlescent steel

It adopts a fluorocarbon coating system. The mica pigment used in finish coating has unique pearl effect. It

is suitable for roof and wall maintenance systems and meets extremely personalized and artistic color

requirements and the requirements of very creative modern buildings.

Clean COLORBOND? steel Spectrum Series

It adopts a special nano-strengthening polyester coating system. The unique finish coating with pearl gloss

contains a mica pigment. With different light illuminations and view angles, variable fantastic colors are

refracted by the color coating layer to give a unique metal appearance of buildings and achieve an aesthetic

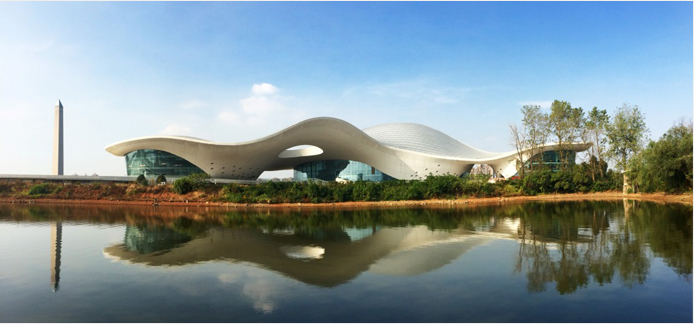

sense of buildings. It is able to sufficiently fulfill various modern building ideas. It is especially

suitable for large-scale public buildings, landmark buildings and buildings with highly personalized

requirements.

Clean COLORBOND? XTM steel

It adopts a special nano-strengthening polyester coating system and a new production process to perfectly

integrate a mica pigment into paint systems. Distinctive paint formulation considerably improves the light

reflection effect of paint surfaces to make full use of beauty of light changes in natural environments, so

that the pearl effect of product can be more changeable and artistic to make your buildings become shiny and

remarkable.

Clean COLORBOND? COOLSMART? steel

It adopts a special nano-strengthening polyester coating system. It is able to maximize the heat reflectivity

of your buildings, so as to reduce energy consumptions, save costs and achieve environment-friendly

requirements. Its color is Summer White? and its SRI can reach 94.

>Aluminium-magnesium-manganese alloy plates

The typical alloy series usually used for roof systems include 3xxx - aluminium

alloy with manganese as main alloy element as well as 5xxx - aluminium alloy with magnesium as main alloy

element.

Typical alloys:A3004,A5052,A5754

Common states:H44,H42

Typical thickness:0.80mm,0.90mm,1.00mm,1.20mm